Over one billion

winds up in the

rubbish every year

… in the form of packaging, beverage cartons, photovoltaic modules

or lithium-ion-batteries. They have one thing in common: they are

all composite materials. As composites they usually end up in the

incinerator or landfill. But they comprise several raw materials that

would be very valuable if they were available on their own.

Imagine what it would be like if the technology existed to break

composites down into their individual components and to reclaim

all the raw materials used.

saperatec

Back to values

saperatec is the first company with the ability to reclaim all

individual raw materials from composite materials, thus making them

available for recycling. With almost 100% recycling quota, saperatec

enables sustainable raw materials management

and an efficient recycling service for

users of its technology.

TECHNOLOGY

Separating

composite

materials using

separation liquids

Using specially developed separation liquids, saperatec offers a

completely new and unique way of separating composite

materials. These separation liquids harness the effect of

special chemical mixture and ensure the separation process in the

appropriate plant technology. The result is reusable individual

materials and thus recycling of the composite material.

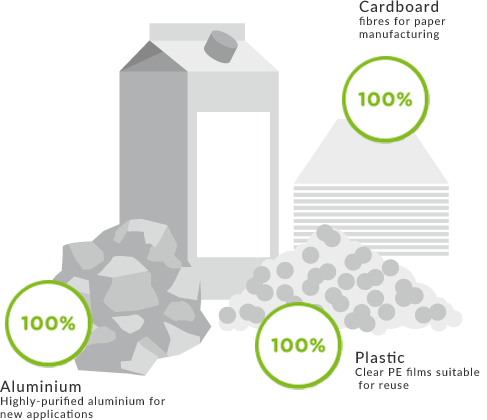

BENEFIT

Up to 100%

added value

its various components without losing or transforming any of

the materials. As these components can then be fed back into

the raw materials cycle, the best possible added value is

achieved. Following the motto: 100% materials in

– 100% materials out.

NEWS

saperatec Opens Facility for Producing Film Plastics from Composite Packaging Waste in Dessau-Roßlau